Side Channel Blower (Imported)

- Flow capacity from 50 – 2,500 m3/h

- Pressures range up to 1000 mbar

- Vacuum range up to -700 mbarg

- Available in single stage, double stage & three stage.

Application Areas

- Vacuum holding on router beds.

- Gas sampling /extraction

- Packaging and labelling machinery

- Drying of materials or to condition agricultural products

- Sub-soil and groundwater remediation.

- Water Treatment Aeration

- Dental Suction Systems

- Methane Gas Extraction

- Spa aeration

- Air sampling

- Pneumatic Conveying Systems

- Lifting and Holding of Parts by vacuum

- Packing machines

- Aeration of Sewage-treatment plants

- Filling of bags/bottles/hoppers

- Thermoforming

- Sorting / enveloping of letters

- Food - processing

- Laser Printer

- Paper processing

- Extrosion Machine

- Aeration of fish ponds

- Simming pool aeration / whirlpools

Industries Served

- Water Supply & Treatment

- Waste-water Treatment

- Wood-working/ cabinet making

- Packaging and Labelling

- Plastics manufacturing

- Grain handling Authorities

- Medical and Dental

- Environmental

- Chemical and Pharmaceutical

- Leisure and Fitness

- Aquaculture

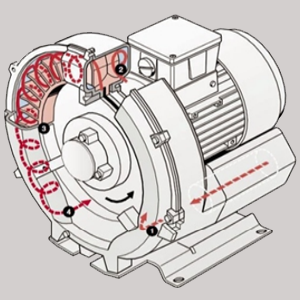

Side Channel Blower Operating Principle

The impellor is mounted directly on the motor shaft for contact free compression. Maximum operational reliability and service life, even at high differential pressure, is ensured by the arrangement of the bearings outside the compression chamber. The gas is taken through the inlet silencer (1). As the gas enters the side channel (2), the rotating impellor (3) imparts velocity to the gas in the direction of rotation. Centrifugal force in the impellor blades accelerates the gas outward and the pressure increases. Every rotation adds kinetic energy , resulting in further increase of pressure along the side channel . The side channel narrows at the rotor, sweeping the gas off the impellor blades and discharging it through the outlet silencer(4).

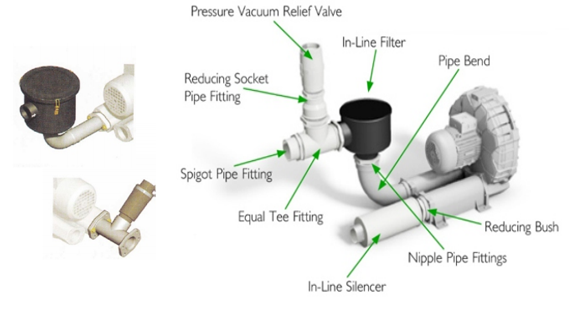

Accessories For Side Channel Blower

- 1) INLINE suction FILTER

- 2) Exhaust silencer

- 3) Elbow connector

- 4) Tee connector

- 5) Vacuum Relief valve

- 6) Pressure relief valve

Data Required For Blower Selection

- DISPLACEMENT CAPACITY ( M3/HR)

- MAXIMUM VACUUM REQUIRED ( MBAR)

- MAXIMUM PRESSURE REQUIRED ( MBAR)

- MOTOR TYPE / ELECTRICAL CLASIFICATION

- ACCESSORIES REQUIRED

- APPLICATION.